Recently, my son disassembled an LED flashlight. He rummaged through the house looking for the right size screwdriver and struggled to remove the miniature screws. I eventually overheard his disappointment from the other room:

Hey! There’s nothing in here that shows how it works - you can’t see the electricity

I chuckled because I remember taking things apart as a boy and occasionally having the same feeling of disappointment when I’d disassemble something only to find a circuit board. I also felt this sentiment recently, when my inkjet printer went on the fritz. Electrical circuits and digital technology provide us many amazing things, but much of digital technology is hidden. I believe this leaves many of us feeling alienated from the technology.

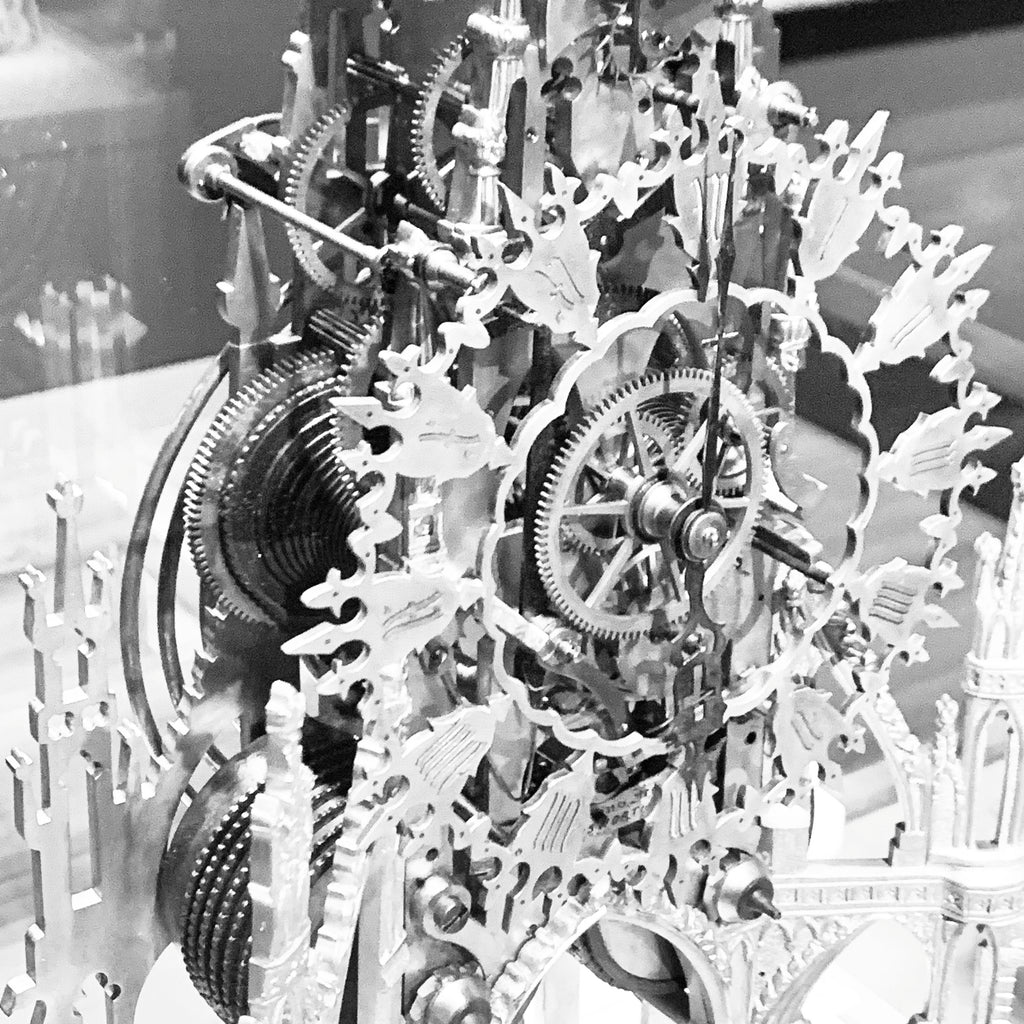

When I lived in Europe, one of my favorite excursions was visiting the Victoria and Albert Museum in London - for an exhibit featuring Victorian era technology. I enjoyed the Greenwich museum of early clocks for all the same reasons. I recall being fascinated by the detailed resolution of steam engines, complex analogue machines, and the first clock prototypes. I felt profound admiration for the engineers who developed the early technology which exposed so many beautiful moving parts. Technology whose gears, pistons, hinges, and pendulums provided visible, comprehensible, and transparent designs. I'm fascinated with Victorian Era designs because the exposed mechanisms and visible systems create a diagram of how the product was made and how it works. I call this idea Transparent Technology.

Transparent Technology is at the core of my philosophy. It is how I see and think. It was embedded in my thesis and it was a part of my architecture practice. Most importantly, it is how I approach all facets of design. To clarify, I'll break down Transparent Technology into four sub-themes: Discursive, Systemic, Didactic, Balance.

Discursivity is the idea of working within a particular discourse, whether it is a language, a material, or mastery of a tool - acknowledging both the opportunities and constraints of its discourse.

Each time I start a design, whether a building or a product, I continuously ask: "how will this be built?" Working out that question is what influences the final design solution.

The forms for several of my chair products were inspired by the history and time contained within layers. The duration of time and type of layers can vary; they can be short intervals represented by the layers of sawdust in my table saw, or can be the epoch's embodied in the sandstone stratification in Southern Utah. Apropos of this idea, I found that the chair's construction can also come from building up layers of plywood like a topographic map.

The language of their construction is evident in the exposed stripes, but also in the exposed ends of the flush dowel pins which were used to align the individual pieces during assembly and gluing.

Before I commit to a final design solution or the final dimension, each product goes through multiple studies, diagrams, and prototypes.

Before I commit to a final design solution or the final dimension, each product goes through multiple studies, diagrams, and prototypes.

The discourse of laminating plywood presents many opportunities for creating form, but my favorite characteristic is the dichotomy between a manufactured materials predictable dimensions and the inherent discrepancies that become exaggerated when the end grain is emphasized as the primary surface.

The discourse of laminating plywood presents many opportunities for creating form, but my favorite characteristic is the dichotomy between a manufactured materials predictable dimensions and the inherent discrepancies that become exaggerated when the end grain is emphasized as the primary surface.

I found that a constraint of this discourse is the inefficiency between irregular shaped chair components, and the rectangular shape of the plywood sheets from which they are cut. Through serendipity, I realized I could reduce this wasted material by incorporating toy parts into the same C.N.C. run. This process of optimizing material is very much like the technique used by a sushi chef who uses the best cut of fish for Sashimi, the next best cut of fish for Nigiri, and the small bits in Maki (rolls).

One toy built from left over chair material is the Tectonic Bison Toy that started as an AT-AT.

A few years ago my son sketched an AT-AT that he wanted to build with me on a Saturday. After we finished building his toy, I was captivated by chunky shape, the mechanical systems, and the blend of wood and stainless steel bolts. I deconstructed it and translated the design language into an American Bison.

I'm fascinated by the way individual systems can be resolved to integrate with other systems to create a well functioning assembly, similar to the coordinated skeletal, muscular, pulmonary, and nervous systems of the human body.

A recent design project was to create a hot rod version of a very under-rated product: the folding chair. The goal was to create a product with exaggerated systems, enhanced mechanics, and raw, exposed parts, while celebrating the folding mechanism and the ephemeral transformation from flat to full. The concept was to visually pull the systems apart so each can illustrate its individual function.

Although I use many forms of digital technology for design and production, my designs all start with analogue studies and prototypes. This study model for the folding chair was built with hot glue, wood and spray paint.

The final solution for the Tectonic Folding Chair has a clear delineation of four individual systems: a sitting system, a stabilization system, a structural system, and a folding system (based on the geometric rules of a parallelogram). All working together to create a sculptural and well-functioning product.

Didactics are the properties of a design that can teach or allow it to be used for learning. I find that the best way to facilitate learning is to bring a system to the surface, as seen in the exoskeleton of an insect. Because its structure is on the outside, it is comprehensible and diagrammatic, resulting in an appearance solely based on the exposed structure.

I have studied the exoskeleton of a grasshopper, a dragonfly, and a bee. Partly because I think they are beautiful, and partly because a few of them came to die in my workshop.

Shortly after the launch of my company a back injury bound me to laying on my stomach for three months. I couldn't lift furniture, let alone build it, so I took the opportunity to develop toy interpretations of my insect visitors.

Originally the toy bugs were intended to be built from wood but the complexity of the mechanisms merited making parts from plastic. I found that using plastics allowed fun colors.

Each insect is intended to embody S.T.E.A.M. education by hosting unique engineering systems to facilitate their movements. The grasshopper features parallelogram guided motion. The bee illustrates force vectors and structural connections. The dragonfly illustrates motion transfer though gears and concentric shafts.

To illustrate these principles, each mechanism is brought to the outside of the insect as an "exomechanism" to diagram how the product works and how it was built.

Although our furniture touts longevity, durability, and long lasting materials. Our toy insects embrace having a shorter life cycle, like the insects which inspired them.

Compared to the steel, wood, aluminum and glass used for the animals and furniture, Tectonic Toy Insects are made from biodegradable corn oil. When someone gets too rough and breaks one, it will decompose much faster than other plastics used commonly for toys.

Finding a simple solution is often a complex challenge and I find the best solutions are often a balance of two opposing ideas.

Many of my designs have been inspired by travel sketching, and for me a metaphor of balance is exemplified by the Japanese Torii gate that I sketched in Kyoto fifteen years ago. The Torii gate symbolizes the transition from the mundane/everyday realm to the sacred.

I have taken the liberty to extend this symbolism of Torii to the idea of products (say a chair, table, or toy) fulfilling a basic function, but also providing sculptural qualities to a space so that the objects themselves become a form of artwork.

The Tectonic Dining Table has formal remnants of its Torii influences, but its language is more about the assemblage of discernible systems that are a diagram of how it is made and how it works.

For more information about our philosophy, history, or products visit our website